Line Polishing Spare Tooling For Plastic Injection Mold 1.2343,1.2311, H13, SKD61, S136

تفاصيل المنتج:

| Place of Origin: | China |

| اسم العلامة التجارية: | FORWA |

| إصدار الشهادات: | ISO9001:2008 ISO14001 |

شروط الدفع والشحن:

| Minimum Order Quantity: | 1 set |

|---|---|

| Packaging Details: | wooden carton |

| Delivery Time: | 35 days do T0 |

| Payment Terms: | T/T |

|

معلومات تفصيلية |

|||

| تسليط الضوء: | Injection Molding Molds,Custom Injection Molding,Custom Injection Molding |

||

|---|---|---|---|

منتوج وصف

Line Polishing Spare Tooling For Plastic Injection Mold 1.2343,1.2311, H13, SKD61, S136

| Product Name: | Spare Tooling For Plastic Injection Mold | Material: | 1.2343,1.2311, H13, SKD61, S136 |

| Surface Finish | Line Polishing | Color: | Natural |

| Standard: | HASCO Copy | Term: | FOB Shenzhen |

Specifications:

| Name | Whith Motorhalter (Plastic Injection Mold) |

| Plastic Material | ABS, PP, PA66, PA6, PPA, PE, TPV, TPU, LDPE, POM,PA+GF, PET, PMMA, PC+ABS, POM+GF, etc. |

| Mold Base Material | SKD11, 1.2312, 1.1730, 1.2311, P20, etc. |

| Cayity & Core Material | H13 HRC48-52, 1.2343, 1.2344, S136, 1.2083, 1.2767, NAK80, etc. |

| Mold Life | 1000K shots or according to customers quantity condition to make it, then will save the cost for our customer. |

| Cavity Number | 1 cavity, 2 cavities, 4 cavities, it is according to customer’s requirements. |

| Runner | Cold runner or Hot runner. |

| Gate Type | Point Gate, Sub Gate, Side Gate, Valve Gate, Edge Gate, Tip Gate etc, the gate will according to the part structure and customer’s requirement. |

| Mold Weight | 2000KG |

| Mold Base Standard | HASCO, DME, LKM local standard, and will according to customer’s requirements. |

| Cycle Time | 35 Seconds |

| Standard of Mold Accessory | LKM, DME, HASCO, MISUMI, MEUSBURGER. |

| Design Soft | UG, CAD, Moldflow etc. |

| File Formats | UG, CAD, Moldflow etc. |

| Injection Molding Machine | From 30T to 250T, total 25 sets machine. |

| MOQ | 1 set |

| Payment | T/T, to be negotiated. |

| Packaging | Wooden case with steel frame. |

| Delivery Time(day) | 35 days T1, according to customer’s requirements. |

| OEM or ODM | Is available |

| Mould Logo | Based on customer requirements. |

| After Sales Service | One year warranty. |

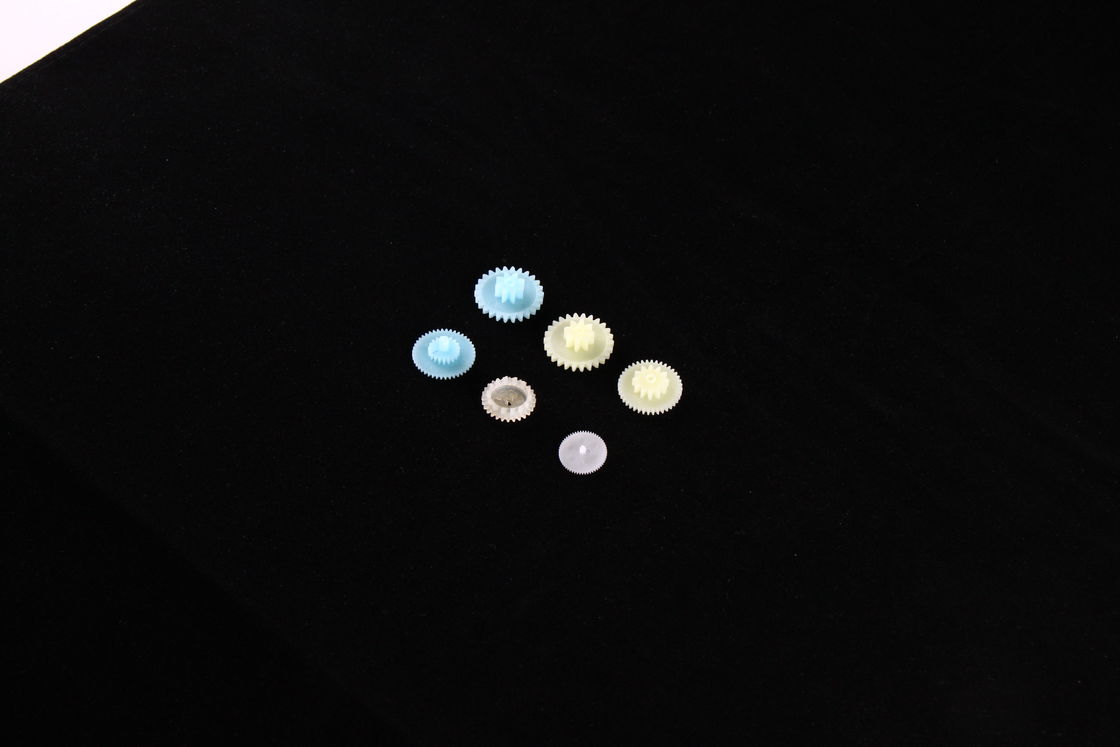

This procut is made of POM plastic material and it is one of the components of the reputation brand electronic parts. The mold construction is complicated and there are many inserts, sliders, lifters and ejector pins, so it has a very high technical requirement for mold design. The mold is a cold runner mold with the best water cooling system and the part can be molded by automatically.

This part has very high size requirements, the defect showed below will not be acceptable, for example, weld line, dark spot , sliver marks, gas traps effect, visible ejection marks, deformation, short shot filling, burnt streaks, sink marks, flash, over dimension, under dimension, street crack etc, moreover, the product finishing surface must meet the requirements of MT11010.

If the mold choose the hot runner, the mold key advantages showed below:

1. Clamping pressure can be lower

2. Cooling time is faster

3. Cycle time is faster

4. Energy consumption lowered

5. Injection pressure can be lower

6. Injection process is cleaner

7. Injection gate are on better locations

8. Labor costs for removing the part from the mold and separating runner scrap from the part are eliminated.

9. Output increased

10. Overall profitability increased

11. Possibility of contamination is lessened with no runners

12. Possibility of producing the parts using small injection machines

13. Problems on nozzle freeze or sprue sticking are eliminated

14. Production costs are lowered

15. Production steps are shortened

16.quality of the plastic part is better

17. Regrinding is eliminated

18. Resin costs are lowered

19. Runner scrap eliminated or reduced

20. Runner weight reduces shot size

Specifications:

| Name | Whith Motorhalter (Plastic Injection Mold) |

| Plastic Material | ABS, PP, PA66, PA6, PPA, PE, TPV, TPU, LDPE, POM,PA+GF, PET, PMMA, PC+ABS, POM+GF, etc. |

| Mold Base Material | SKD11, 1.2312, 1.1730, 1.2311, P20, etc. |

| Cayity & Core Material | H13 HRC48-52, 1.2343, 1.2344, S136, 1.2083, 1.2767, NAK80, etc. |

| Mold Life | 1000K shots or according to customers quantity condition to make it, then will save the cost for our customer. |

| Cavity Number | 1 cavity, 2 cavities, 4 cavities, it is according to customer’s requirements. |

| Runner | Cold runner or Hot runner. |

| Gate Type | Point Gate, Sub Gate, Side Gate, Valve Gate, Edge Gate, Tip Gate etc, the gate will according to the part structure and customer’s requirement. |

| Mold Weight | 2000KG |

| Mold Base Standard | HASCO, DME, LKM local standard, and will according to customer’s requirements. |

| Cycle Time | 35 Seconds |

| Standard of Mold Accessory | LKM, DME, HASCO, MISUMI, MEUSBURGER. |

| Design Soft | UG, CAD, Moldflow etc. |

| File Formats | UG, CAD, Moldflow etc. |

| Injection Moulding Machine | From 30T to 250T, total 25 sets machine. |

| MOQ | 1 set |

| Payment | T/T, to be negotiated. |

| Packaging | Wooden case with steel frame. |

| Delivery Time(day) | 35 days T1, according to customer’s requirements. |

| OEM or ODM | Is available |

| Mould Logo | Based on customer requirements. |

| After Sales Service | One year warranty. |

![]()