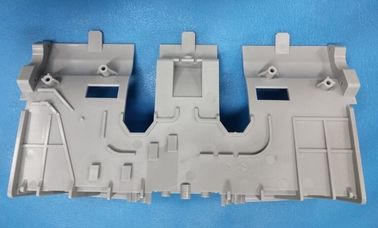

Injection Molded Plastic Parts ABS Material Use For Bank Machine Interior Parts

تفاصيل المنتج:

| Place of Origin: | China |

| اسم العلامة التجارية: | FORWA |

| إصدار الشهادات: | ISO9001:2008 ISO14001:2004 |

| Model Number: | D-20170825 |

شروط الدفع والشحن:

| Minimum Order Quantity: | Negotiation |

|---|---|

| الأسعار: | Negotiation |

| Packaging Details: | Mold : packed by wood carton , Plastic parts : box |

| Delivery Time: | 30days T1 |

| Payment Terms: | T/T |

| Supply Ability: | 40sets per month |

|

معلومات تفصيلية |

|||

| Product Name: | Plastic injection mold parts | Cavity: | 1*1 |

|---|---|---|---|

| Core/Cavity material: | P20 HH | Runner system: | cold runner |

| Standard: | DME COPY | Raw material: | ABS |

| تسليط الضوء: | Custom Plastic Injection Molding,Plastic Mould Parts,Plastic Mould Parts |

||

منتوج وصف

Injection Molded Plastic Parts ABS Material Use For Bank Machine Interior Parts

Injection Mold parts ABS material use for bank machine interior parts

Specifications:

| Office Automation | Size | Depends on customers requirement (2D/3D) |

| Color | All | |

| Function | communication | |

| Use | Electrical application,Printer,Fax, | |

| Brand | Canon, Epson, Brother, Sony, Tyco, Audi, Honda, Toyota and Flextronics, Fuji Xerox, HP, JST, Kyocera, Panasonic, BMW, Sanyo, ZTW | |

| Mould | Type | Prototype mold and series/production mold |

| Standard | Hasco copy,DME copy,LKM,FUTABA,other | |

| Cavity/Core material | 1.2343/1.2311/SKD61,S136,NAK80,H13,738H,other | |

| Injection | Cold runner/hot runner(Moldmaster,YUDO,INCOE,HUSKY,MOLD-TIP,other | |

| Cycle life | 500k~1000k shots | |

| Service | One stop service | Design- Mockup- Manufacturing- Assembly |

| Design |

CAD/CAM technical platform and perfect engineering data switching system which enable us to have elastic choices to offer service to our customers. UG 4.0 DXF, DWF, PRT, SAT, IGES or STE format for mold design and layout |

|

| Mockup | Rapid laser mockup /CNC mockup process | |

| Manufacturing | Prototype mold,production mold,plastic parts production | |

| QC |

Latest precise detecting instruments Well trained and skillful inspectors Timely feedback to manufacturing department High yield rate and timely delivery

|

|

| Delivery |

SAMPLES SHIPPED BY FEDEX,DHL,TNT,UPS Sea or air shipment for Mold/mass production |

The company is well organized to create the team in each project so that the products customer requires are timely released. The modern production facilities, in Main Factory and in state-of-the-art Shiga Factory, are closely linked to work efficiently as a team that allows the company to transfer jobs quickly from design to production with flexibility and available know-how.

We will always come back to the basic of production and satisfy customer's needs perfectly as a professional team.